Hardware aspect

Hardware

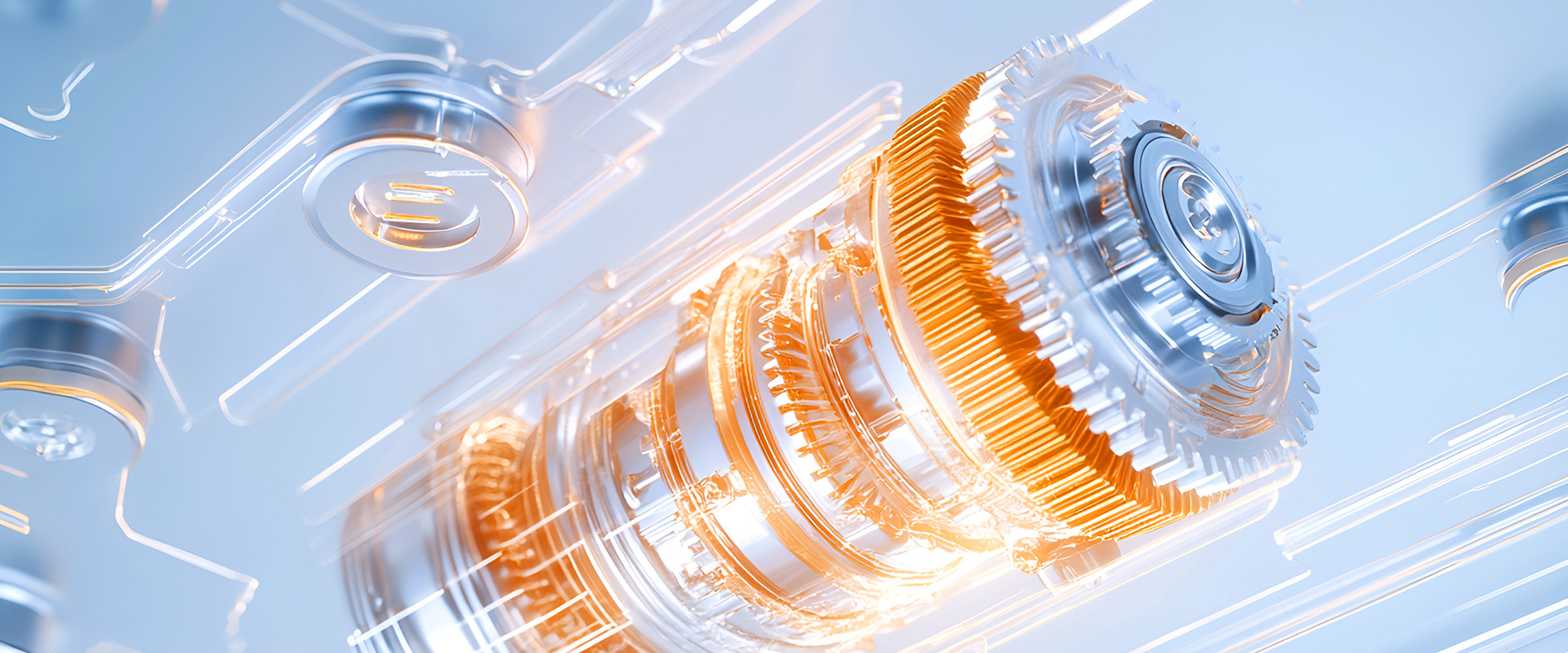

1. Juyue now has 100 gear grinding machines +, 40 strong power honing machines + have arrived one after another, more than 10 imported gear grinding machines, 200 high-speed gear hobbing machines +, 3 gear hub production equipment Grobo equipment, and 30 electron beam welding machines +;

2. There is a complete gearbox shaft gear production line in the whole process, which has successfully served many world head gearbox enterprises such as ZF;

3. The process equipment involved include: CNC lathes, machining centers, turning and milling compounding, hobbing, chamfering, pulling, tooth rubbing, electron beam welding, heat treatment, straightening, cylindrical grinding, inner hole grinding, hole honing, hard turning after heating, tooth grinding, strong force honing and other equipment;

HARDWARE

1. Now has the number of equipment:

Juyue now has more than 100 gear grinding machines, more than 40 strong power honing machines have arrived one after another, more than 10 imported gear grinding machines, more than 200 high-speed gear hobbing machines, 3 gear hub production equipment, and more than 34 electron beam welding machines,3 laser welding machines.

Gear grinding machine

Strong honing

Imported gear machine

High speed gear hobbing machine

Grobo Equipment Gear Hub Equipment

Electron beam welding

2. Production Line & Service Provider:

There is a complete gearbox shaft gear production line in the whole process, which has successfully served many world head gearbox enterprises such as ZF.

3.The involved process equipment

CNC lathes, machining centers, turning and milling compounding, hobbing, chamfering, pulling, tooth rubbing, electron beam welding, heat treatment, straightening, external circular grinding, internal hole grinding, hole honing, hard turning after heating, tooth grinding, strong force honing and other equipment.

Software

I.The MES system has been fully deployed across our production facilities. Through continuous upgrades and optimizations, it has gained unanimous customer approval for its operational excellence.

II.The ERP system has significantly enhanced cross-departmental communication efficiency, ensured data accuracy and consistency, and concurrently driven process standardization across the organization.

III.In 2025, the company will fully implement digital transformation, which will significantly enhance production management capabilities through digital empowerment.

Capacity

1.2000 sets of existing equipment +

2. Existing production capacity: 2.5 million pieces/month

3. Annual output of 30 million pieces/year

2000 + sets of existing equipment

Existing capacity 2.5 million pieces/month

Annual output of 30 million pieces/year

Lean Production Aspects

Quality Software

Significant increase in 1. productivity

Shortened production cycle:Through value stream map (VSM) analysis, non-value-added links are eliminated, and the production cycle of a product is reduced from 15 days to 10 days.

Increased equipment utilization:After the implementation of TPM (full production maintenance), the equipment failure rate decreased by 20%, and OEE (equipment comprehensive efficiency) increased from 55% to 75%.

Inventory reduction:The JIT (just-in-time production) model has reduced raw material inventories by 35 per cent and work-in-progress inventories by 50 per cent.

Significant improvement in 2. quality levels

Decreased defect rate: Through standardized operations and the gradual introduction of error-proof (Poka-Yoke) design, the product defect rate decreased from 3.5 percent to 1.8 percent.

Rework reduction:Quality problems are controlled at the source and rework costs are reduced by 30%.

Reduced customer complaints:The complaint rate of a key customer dropped from 5 to less than 1 per month.

3. cost control effect is remarkable

Waste reduction:By eliminating the seven major wastes (such as overproduction, waiting, handling, etc.), the cost savings are nearly 2 million.

Human optimization:The multi-functional training and flexible production line layout have reduced the manpower demand by 15%, while the skill level of employees has been greatly improved.

Energy savings:Reduce workshop energy consumption by 10% through lean improvement.

4. Employee Engagement and Cultural Change

All staff improve awareness:Through continuous improvement activities, the enthusiasm of employees to participate in improvement is stimulated, and the sense of gain of employees is greatly improved.

Team Collaboration Enhancements:Cross-departmental collaboration mechanisms (such as rapid response teams) can reduce problem resolution time by 50%.

Increase in employee satisfaction:Improvements in the work environment and improved skills have reduced employee turnover from 12 per cent to 7 per cent.

5. customer response and market competitiveness enhancement

Shortened lead time:The average time from receipt to delivery was reduced from 90 days to 60 days, and customer satisfaction increased by 20%.

Enhanced customization capabilities:The flexible production line reduces the lead time for small-volume customized orders by 30%.

Market share expansion:Product market share increased significantly.

Upgrade of 6. management mode

Data-driven decision making:Through real-time monitoring of lean indicators, management decisions are more scientific.

Continuous improvement mechanism:Establish monthly lean review meetings to ensure normalization of improvement activities.